Light duty CNC lathe CN-FD66,CN-FD75

1. Max. Turning diameter on the bed: 500mm

2. Max. Turning length:1080mm

3. Max. Turning diameter:230mm

4. X/Z axis repeat position accuracy:±0.0025/±0.005

5. Spindle speed range:35-4000r/min

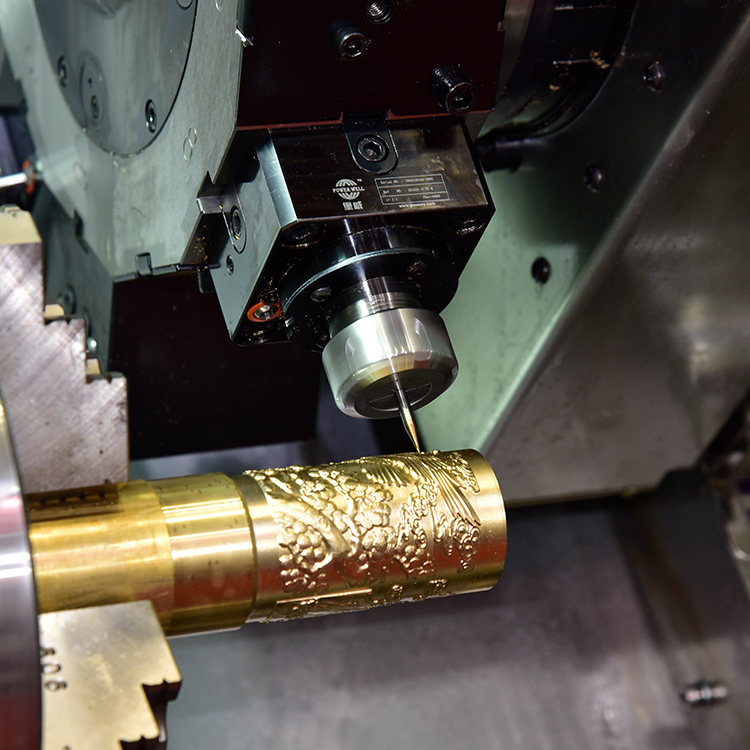

Introduction

Adopt the structure of Y-axis power cutter tower,with a wide machining range(the maximum machining diameter can be up to 230mm;The maximum processing length can be up to 230mm;The maximum processing length can be up to 240-400mm),greatly improve the process flexibility;High power head speed(up to 4,000-6,000 rotations in a continuous 24h),greatly improve the processing efficiency of the unit output;

The base of machine tool is optimized by finite element analysis and has good rigidity.

The X/Z axis adopts pre-tensile structure,which reduces the influence of thermal deformation on the precision of X/Z axis and improves the rigidity of X/Z axis.

characteristic

Chip removal mode can be side discharging or back discharging,which has the strong adaptability to workshop layout.

This machine is especially suitable for processing shaft,pipe and disc parts,with the advantages of fast speed,high precision,good finish,and stability of the size consistency,etc.

Main Specification

| Model of lathe | CN-FD66 | CN-FD75 | |||

| Main specifications | Max. swing diam. over bed | 500mm | 520mm | ||

Processing range | Max. Turning length | 280/430/730/1080mm | 475mm | ||

| Max. Turning diameter | 230mm | 310mm | |||

| Diameter of the bar | 65mm | 74mm | |||

Weight capacity(Disks) | 90kg | ||||

Weight capacity(Shaft parts) | 150kg | ||||

Accuracy | X/Z axle repeat position accuracy | ±0.0025/±0.005 | |||

X/Z axle position accuracy | ±0.005/±0.008 | ||||

| Man-machine handling distance | Height of the center(From the bottom of machine) | 980mm | 1125mm | ||

Spindle

| The forms and codes of spindle end | A2-6 | A2-8 | ||

| Spindle head collect taper | Ø83,1:20 | Ø100,1:20 | |||

| Spindle hole diameter | 79mm | 90mm | |||

Spindle headstock | Spindle speed | 30-3000r/min | |||

| Spindle speed series | Stepless | ||||

Spindle speed conversion | Automatic input | Circumferential velocity | |||

Manual input | Continuous control | ||||

The motor performance | Main motor output power | The 30-minute rating | 15 KW | 18.5KW | |

| Continuous rating | 11KW | 15KW | |||

| X/Z /Y/S motor torque | 15/10/10/10 N.m | ||||

| Hydraulic clamping | Standard chuck | Diameter of chuck | 8 inch | 10 inch | |

Feed shaft performance | X axle rapid movement speed | 20m/min | |||

| Z axle rapid movement speed | 24m/min | ||||

| X axle linear guide rail | 35 roller type | ||||

| Z axis linear guide | 35 roller type | ||||

| Travel of X axle | 135mm | ||||

| Travel of Z axle | 310/460/760/1110mm | 680mm | |||

Tail stock performance | The tailstock sleeve diameter | 60mm | 85mm | ||

| Travel of tail stock sleeve | 120mm | ||||

| Spindle collect taper of the tailstock | Morse 4 | ||||

| Max.thrust of tailstock sleeve | 8000N | ||||

| The tailstock body trip | 4000mm | ||||

Turret performance | Type of the turret | Horizontal power 12 station(with Y axis) | |||

| Turret transfer time:every workstation/180° | 0.12 sec | ||||

Max. Tool speed | 4000r/min | ||||

Y-axis travel | ±50mm | ||||

| The turret could be swapped or not | Yes | ||||

| Size of the round knife | 20 x 20 mm | ||||

Boring bar diameter | Ø32 | ||||

Power tool holder | ER25(Ø1-16) | ||||

Machine dimension(L x W x H) | 3134mm x 1800mm x 1900mm | ||||

| Weight | 4800kg | ||||

Contact Us

![]() +86 13928187729

+86 13928187729

![]() +86 13928187729

+86 13928187729

![]() manager@southlathe.com/ js_john@vip.163.com

manager@southlathe.com/ js_john@vip.163.com

![]() No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.

No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.