Featured Products

CNC Machine Manufacturer

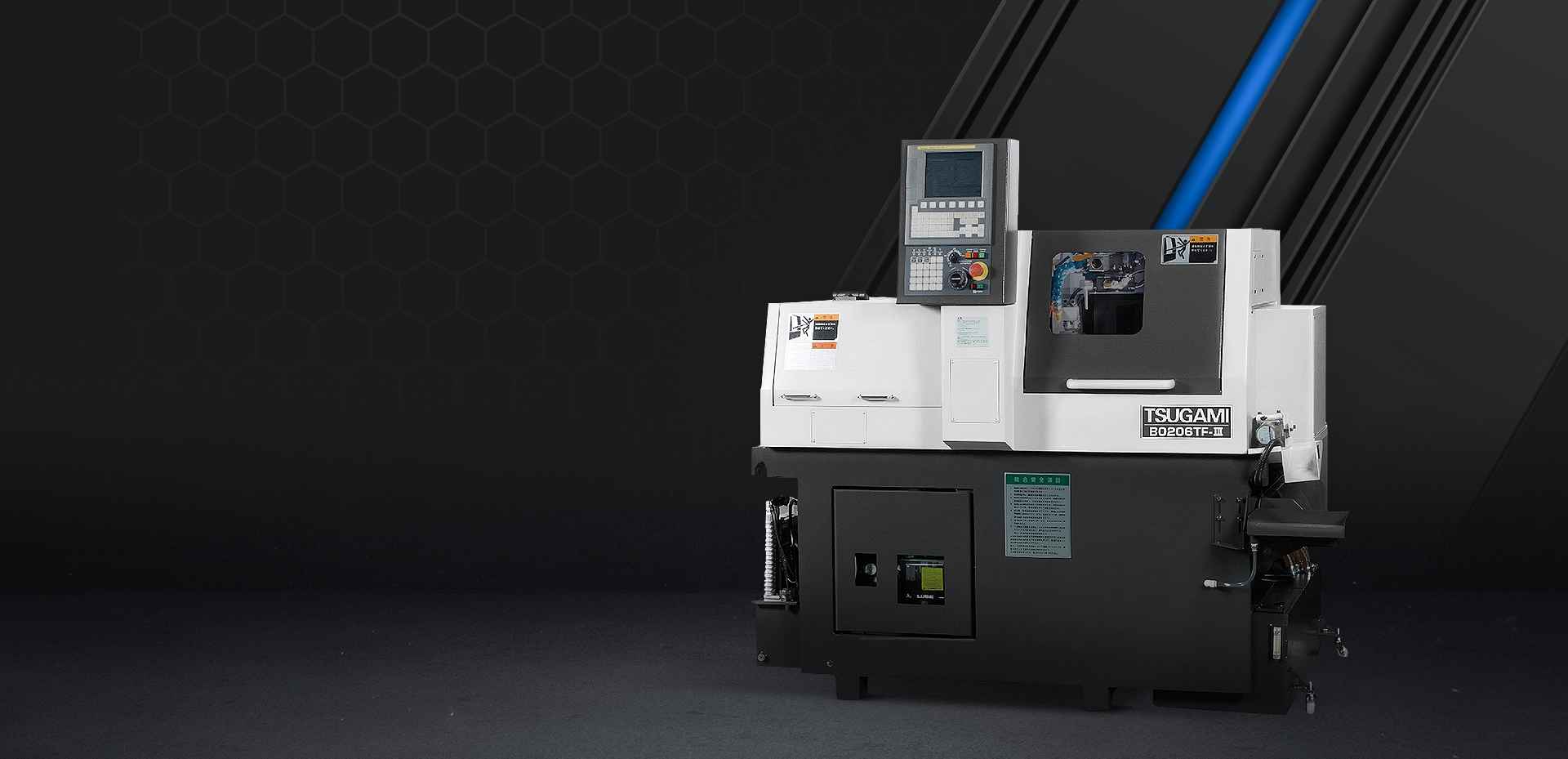

As a leading CNC machine supplier, SOUTH Lathe offers a wide range of lathe machine products, include swiss lathe, heavy duty CNC lathe, CNC machining center, etc.

To guarantee the stability of the machine tool quality, the machine body and configuration design adopt the unified accessories, the machine tool has simple and reasonable structure, pay attention to the actual situation, and is used conveniently.

Why Choose Us

provide the completed solutions for cnc machining

One-Stop Solution

OEM and ODM service

As a CNC machine manufacturer with a focus on innovation in the machine tool construction sector, we hope that our respected customers can make the careful and meticulous contrast and understanding of numerical control lathe configuration, and you will never regret buying the numerical control lathe which is genuine at a fair price and can reach the turning effect. The variety of production solutions means that CNC lathes from SOUTH Lathe have been working reliably in all industries for decades.

We have widespread products containing series of CNC machines, which iincludes Swiss lathe, Heavy duty CNC lathe, Turn-Mill Centers, Vertical Machining Centers (VMC), Horizontal Machining Centers (HMC), 5 Axis Machining Centers, etc.

SOUTH lathe is a professional CNC machine manufacturer of turning-milling drilling, tapping and carving combined machine tool. To guarantee the stability of the machine tool quality, the machine body and configuration design adopt the unified accessories (change cutter holder, power head or tool turret on the cutter bed-plate), the machine tool has simple and reasonable structure, pay attention to the actual situation, and is used conveniently.

We hope that our respected customers can make the careful and meticulous contrast and understanding of numerical control lathe configuration, and you will never regret buying the numerical control lathe which is genuine at a fair price and can reach the turning effect.

Our CNC lathes factory has passed the ISO 9001 international quality certification. We provide OEM and ODM service for the customers.

News Center

Contact Us

![]() +86 13928187729

+86 13928187729

![]() +86 13928187729

+86 13928187729

![]() manager@jeasoncnc.com / js_john@vip.163.com

manager@jeasoncnc.com / js_john@vip.163.com

![]() No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.

No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.