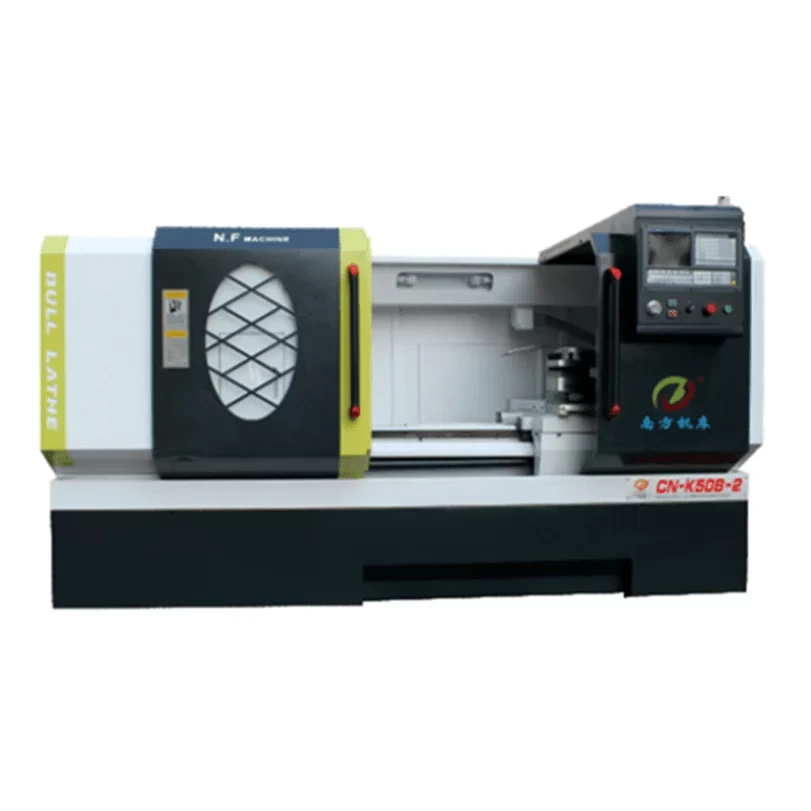

500mm swing over bed CNC lathe –1000mm machining length1

Main performance(CN-K50B-1000):

1. One piece casting base and bed, keep high rigidity, good accuracy and stable performance.

2. Swing over bed diameter. :500mm

3. machining length 1000mm

4. Distance between guild way on Z-axis of the bed:420mm

5. Distance between guild way on X-axis of the bed:230mm

6. Centre of height: 265mm.

7. Spindle bore 82mm.

8. Spindle without gear box, motor driving directly

9. Beijing 11kw servo motor.

10. Spindle head model: 1:20 / Ø90

11. Independent spindle, it is very better to machine casting work piece and heavy duty.

12. GSK 980 controller

13. Servo motor, thread device, automatic lubrication, full cover protection for ball screw and lead rails.

500mm swing over bed CNC lathe –1000mm machining length

Main performance(CN-K50B-1000):

1. One piece casting base and bed, keep high rigidity, good accuracy and stable performance.

2. Swing over bed diameter. :500mm

3. machining length 1000mm

4. Distance between guild way on Z-axis of the bed:420mm

5. Distance between guild way on X-axis of the bed:230mm

6. Centre of height: 265mm.

7. Spindle bore 82mm.

8. Spindle without gear box, motor driving directly

9. Beijing 11kw servo motor.

10. Spindle head model: 1:20 / Ø90

11. Independent spindle, it is very better to machine casting work piece and heavy duty.

12. GSK 980 controller

13. Servo motor, thread device, automatic lubrication, full cover protection for ball screw and lead rails.

| Model

Specification |

CN-K50B-1000 | |

| Main spec | Swing over bed | 500mm |

| Max length of machining work piece | 1000mm | |

| Capacity | Max machining diameter on bed | 500mm |

| Max machining diameter on slider | 280mm | |

| Max length of machine(distance between tailstock to chuck jaws) | 930mm | |

| Bar through material diameter | Ø80mm | |

| Spindle center height | 265mm | |

| Center distance between tailstock to spindle | Distance between spindle to tailstock | 1050mm |

| Spindle | Spindle bore diameter | Ø82mm |

| Taper of spindle bore | C8 / 1:20 / Ø90 | |

| Range of spindle speed | Continuously transfer 50-2500rpm | |

| turret | Max. travel of turret on Z axis | 1020mm |

| Max. travel of turret on X axis | 310mm | |

| Rapid move speed on Z axis | 8000mm/min | |

| Rapid move speed on X axis | 6000mm/min | |

| Turret positions | vertical type 6 positions turret | |

| Turret size | 25×25 mm | |

| Distance between spindle center to the support surface | 25mm | |

| Tailstock | Taper of spindle sleeve | MT5 |

| max travel of tailstock sleeve | 150mm | |

| max travel of Tailstock on X-axis | ±15mm | |

| Motor | Main motor power | 11 kw servo motor |

| Torque of Z axis motor | 1.5 kw(10N.m) | |

| Torque of X axis motor | 1.2 kw(6N.m) | |

| Cooling pump | AYB-20 0.115kw | |

| Tool holder model | LD4 | |

| Outline dimensions | 1000mm model | 3100mm x 1260mm x 1600 mm |

| Weight | 1000 mm model | 2500 kgs |

Machine inspection precision

| Inspection item | China Standard | Factory standard |

| Machining precision | IT7 | IT7 |

| Machining work piece roundness | 0.005mm/φ50mm | 0.004mm/φ50mm |

| Machining work piece cylindricity | 0.03mm / 300mm | 0.02mm / 200mm |

| Machining work piece planeness | 0.025mm/φ300mm | 0.015mm/φ200mm |

| Machining work piece surfaceness | Ra2.5μm | Ra2.0μm |

| Position precision | X-axis 0.03mm | X-axis 0.024mm |

| Z-axis 0.04mm | Z-axis 0.032mm | |

| Re-position | X-axis 0.012mm | X-axis 0.01mm |

| Z-axis 0.016mm | Z-axis 0.012mm |

Machine configuration

| Accessories Name | Specifications Model | Manufacturer | Remark |

| CNC | GSK980 | GSK | |

| The main motor | 11KW spindle servo motor | China Beijing CBT | |

| X-axis motor | 110ST-M06030 | GSK | |

| Z-axis motor | 130ST-M10025 | GSK | |

| Spindle bearing | P4 | China famous HRB bearing | |

| P5

P4 |

|||

| Spindle | 82 mm Spindle | Southern Machine | |

| Turret | Vertical 6 positions turret | HTC LD4 | |

| X-axis ball screw | C3 | Bot / Han River | |

| Z-axis ball screw | C3 | Bot / Han River | |

| Screw bearings for X-axis ball screw | P4 | HRB/Luo axis research | |

| Screw bearings for Z-axis ball screw | P4 | HRB/Luo axis research | |

| Three-color light | Three color flashing | ONN | |

| The key electrical components | Relay/Contactor | Japan’s Izumi/Switzerland ABB/Schneider | |

| tailstock | China South brand | South CNC |

The standard machine tool accessories:

| No. | accessory name | Model Specifications | Quantity | Remark |

| 1 | Adjust the horn and bolts | CN-K50B | 1 | Our |

| 2 | Pan tools | 1 | Three gulls | |

| 3 | Screw tools | 1 | China brand | |

| 4 | Chuck | Manual jaw chuck diameter Φ250 | 1 | China brand |

Technical data:

| No. | Technical data Name | Copies | Remark |

| 1 | Manual machine tool (machine)—mechanic and electric | 1 | |

| 2 | Certificate | 1 | |

| 3 | Precision inspection | 1 | |

| 4 | Packing List | 1 | |

| 5 | Manual user operation for controller | 1 | |

| 6 | Controller system operation manual | 1 | |

| 7 | Electric diagram | 1 |

Contact Us

![]() +86 13928187729

+86 13928187729

![]() +86 13928187729

+86 13928187729

![]() manager@southlathe.com/ js_john@vip.163.com

manager@southlathe.com/ js_john@vip.163.com

![]() No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.

No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.