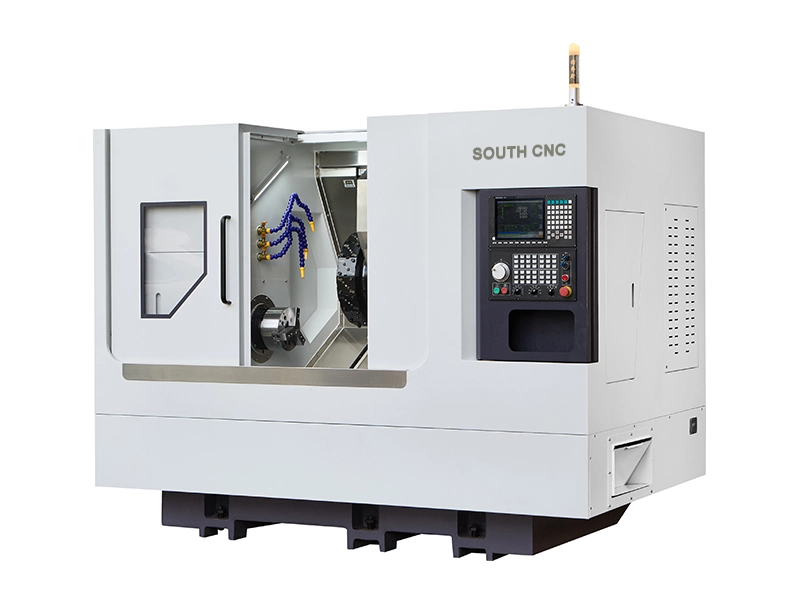

cnc lathe turning center CK76DTYW

Main performance

◉ Swing over lathe diameter 600mm

◉ Max. turning length 430mm with tail stock

◉ One piece casting base and slanting bed keep good stable machine performance

◉ Spindle bore 86mm

◉ Maximum turning diameter Ø230mm

◉ Taiwan SYNTEC controller

◉ The 0° power head can reach 8000 rpm during normal operation, while the 90° power head can reach 6500 rpm during normal operation.

◉ The turret has no gear module transmission, eliminating heat sources and ensuring machining accuracy.

◉ Highlight turning and milling capabilities extend tool life.

◉ Programmable tailstock control.

◉ Turning and milling functions enable machining of complex materials such as stainless steel, titanium alloy, and carbon steel.

Product advantages

◉ Chip removal options: Side and rear chip removal, integrated and adjustable.

◉ The integral casting undergoes annealing, vibration, and other aging processes to ensure long-term machining stability and machine tool life.

◉ Equipped with high-rigidity spindle unit for stable cutting performance under heavy load conditions, ensuring consistent accuracy across long production runs. The integrated L-shaped bed structure minimizes vibration and thermal deformation, enhancing overall machining stability. All linear guide ways are sealed and protected against chips and coolant, extending service life and maintaining precision over time. Automatic lubrication system ensures optimal operation of all moving parts, reducing maintenance frequency and downtime. The compact layout maximizes floor space efficiency without sacrificing accessibility for tool changes or workpiece loading.

Main Specification

|

Model of lathe |

Unit |

CK76DTYW |

|

|

Machining capacity |

Max. swing diameter over lathe |

mm |

Ø600 |

|

Max. turning length |

mm |

430 |

|

|

Maximum turning diameter |

mm |

Ø230 |

|

|

Spindle |

Spindle center height |

mm |

1150 |

|

Spindle model |

---- |

A2-8 |

|

|

Spindle bore diameter |

mm |

Ø86 |

|

|

Max. Bar material |

mm |

Ø72 |

|

|

Max. Spindle speed |

r/min |

4000 |

|

|

Spindle motor power/torque |

Kw/Nm |

15Kw/143Nm |

|

|

Power turret |

Power turret model |

- |

BMT55-16T |

|

Turret motor power |

KW/ N.m |

7.5KW/22 N.m |

|

|

Power turret tool max. speed |

rpm |

8000 |

|

|

X/Z/Y axis feeding |

X/Z axis max. fast travel speed |

m/min |

24 |

|

Y axis max. fast travel speed |

m/min |

15 |

|

|

X/Z/Y axis motor power/torque |

KW/ N.m |

YASKAWAI1.8KW/11.5Nm |

|

|

X/Z/Y -axis C3 grade ball screw |

mm |

32/32/40 |

|

|

X-axis Roller P4-level linear rail |

mm |

35/35/35 |

|

|

X-axis maximum travel |

mm |

248 |

|

|

Z-axis maximum travel |

mm |

460 |

|

|

Y-axis maximum travel |

mm |

112(±56) |

|

|

Axial power tool offset spindle center |

mm |

30 |

|

|

tailstock |

Tailstock travel |

mm |

450 |

|

Ejector taper hole |

MK |

Morse 5# |

|

|

Equipment specifications |

Machine net weight |

kg |

4200 |

|

Total horse |

KW |

28.5 |

|

|

Machine L x W x H |

mm |

2450 x1700 x 2000 |

|

Optional items

(Standard ● Optional ○)

|

Configuration item |

CK76DYTW |

|

|

Spindle |

Mechanical spindle |

● |

|

Electric spindle |

○ |

|

|

Control system |

SYNTEC controller |

● |

|

Feed axis |

Yaskawa |

● |

|

SYNTEC |

○ |

|

|

Turret |

BMT55 Power Turret |

● |

|

BMT65 Power Turret |

○ |

|

|

Tailstock |

Morse 5# |

○ |

|

Clamping |

Back-pulling chuck |

● |

|

Chuck |

○ |

|

|

Auxiliary equipment |

Parts collect device |

○ |

|

Feeding device |

○ |

|

|

Chip conveyor |

○ |

|

|

Automated robot |

○ |

|

|

Oil mist separator |

○ |

|

Contact Us

![]() +86 13928187729

+86 13928187729

![]() +86 13928187729

+86 13928187729

![]() manager@southlathe.com/ js_john@vip.163.com

manager@southlathe.com/ js_john@vip.163.com

![]() No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.

No.3 Huafu Road, Bianjiaojuweihui, Ronggui town Shunde Foshan City, Guangdong Pronvice China.