Cnc Machine | SOUTH Lathe

One-Stop Solution

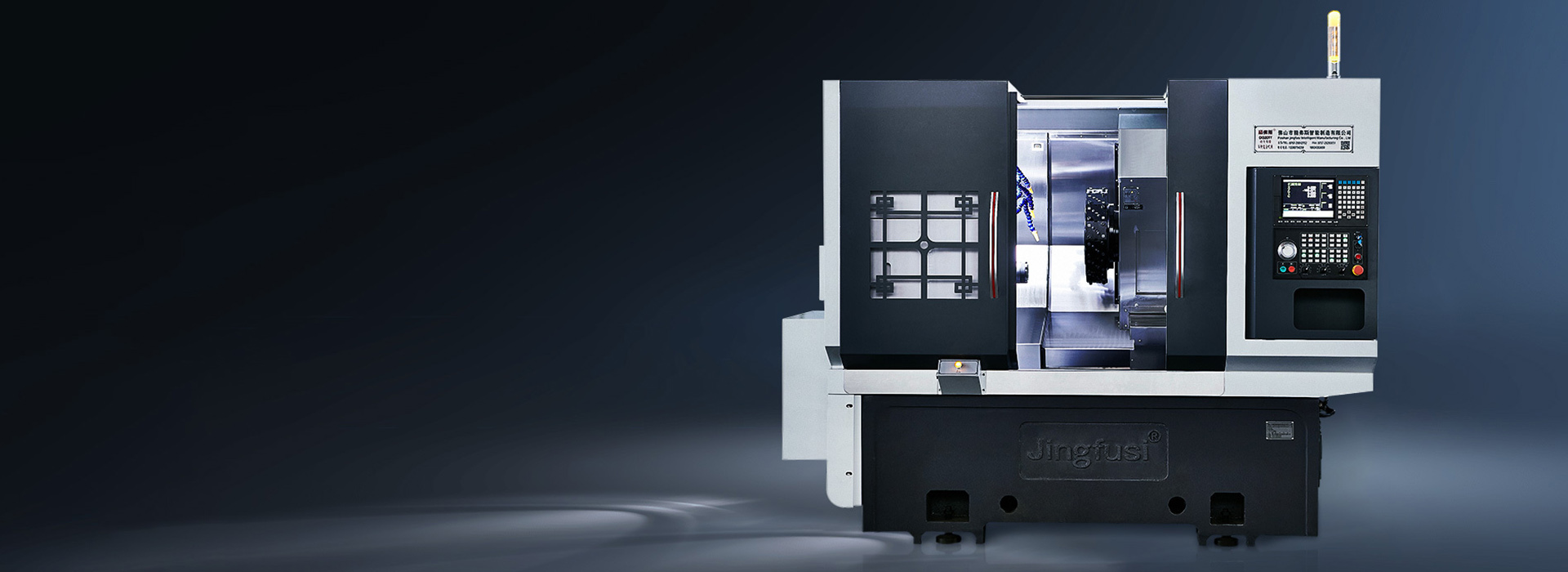

CNC Machine For Metal Processing

Elevate your production capabilities with state-of-the-art CNC machining centers designed for ultimate versatility and efficiency. Perfect for manufacturers seeking precision, speed, and adaptability, our CNC solutions redefine modern machining. Here’s why industry leaders choose us:

Machine Selection

By gathering detailed specifications from the customer or project team, SOUTH LATHE ensures that the CNC equipment is designed to meet the performance and operational demands of the specific application.

SOUTH lathe is a professional CNC lathe machine manufacturer of turning-milling drilling, tapping and carving combined machine tool. To guarantee the stability of the machine tool quality, the machine body and configuration design adopt the unified accessories (change cutter holder, power head or tool turret on the cutter bed-plate), the machine tool has simple and reasonable structure, pay attention to the actual situation, and is used conveniently.

A Swiss CNC lathe may benefit your machine shop if you produce small, complex parts in high volumes, requiring precision and accuracy, as it enhances efficiency, quality control, and reduces labor costs.

The decision to invest in a Swiss CNC lathe should be based on a careful evaluation of your facility’s specific needs and resources. It’s important to work with an experienced supplier or manufacturer to ensure that you choose the right machine for your operation.

Our factory has passed the ISO 9001 international quality certification. We provide OEM and ODM service for the customers.